WRAPTITE CARBON FIBER ENCAPSULATION

Arnold Magnetic Technologies offers composite and metallic encapsulation solutions for a wide range of permanent magnet systems and applications.

While metallic sleeved magnet containment solutions are used extensively for magnet containment, Wraptite composite sleeves offer a superior design alternative for today’s higher performance applications in which rotational speeds exceed 50K RPM. In addition to RPM, Wraptite magnet encapsulation is a perfect fit for systems that must operate reliably in extreme conditions while reducing system weight. Applications with these characteristics are found in automotive, motorsport, oil and gas, aerospace and general industrial systems.

Learn more in our Carbon Fiber Rotor Encapsulation Tech Talk:

WRAPTITE CARBON FIBER ENCAPSULATION

Arnold Magnetic Technologies offers composite and metallic encapsulation solutions for a wide range of permanent magnet systems and applications.

While metallic sleeved magnet containment solutions are used extensively for magnet containment, Wraptite composite sleeves offer a superior design alternative for today’s higher performance applications in which rotational speeds exceed 50K RPM. In addition to RPM, Wraptite magnet encapsulation is a perfect fit for systems that must operate reliably in extreme conditions while reducing system weight. Applications with these characteristics are found in automotive, motorsport, oil and gas, aerospace and general industrial systems.

ENCAPSULATED MAGNET APPLICATION EXAMPLES

KERS — Kinetic Energy Recovery System, which includes a composite sleeved RECOMA® SmCo magnet rotor for a 50,000+ RPM, 100KW+ system

Electric Turbo Charger — Inconel or composite sleeved RECOMA® SmCo magnet rotor incorporating Arnon Silicon Steel thin laminations that operates at > 100,000 RPM

High Power Density Cabin Air Pressure Motor — Inconel-sleeved RECOMA® SmCo balanced rotor, which is part of 180KW system that operates up to 170°C

WRAPTITE MATERIALS OPTIONS

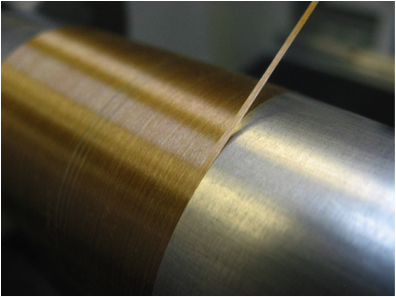

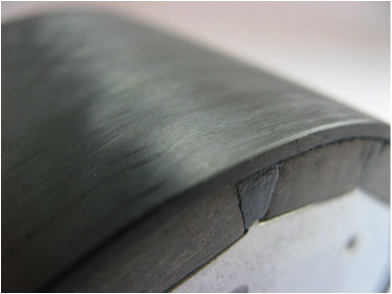

Wraptite composite materials include carbon composites using a range of epoxy and resin systems. Our technology includes the winding of multi-filament tows directly over the rotor to be contained, or the production of sleeves which are pressed into position to produce an interference fit.

Wound in place

Pressed on sleeve

Arnold Magnetic Technologies offers a customized service and is able to assist in the engineering design of your rotor and containment requirements. Arnold provides a total in-house solution, from design concept through system integration.