MAGNETIC FIELDS TECHNOLOGY

Arnold’s patented Shaped Field Magnet (SFM) technology offers new options for designers of next-generation rotating equipment and sensor systems, whether designing new systems or looking to boost efficiency in existing equipment. By managing the magnetic field distribution, Arnold’s Shaped Field Magnets provide enhanced performance and offer greater design flexibility— often at a lower cost. Shaped Field Magnets can also replace standard permanent magnets in existing equipment, providing improved efficiency and performance.

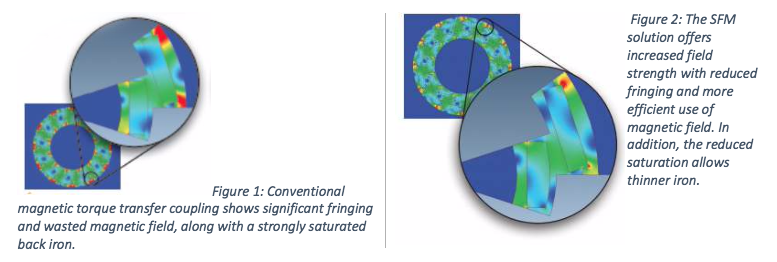

In a traditional magnet, the anisotropy within and outside a magnet is made as uniform as possible. A Shaped Field Magnet has a field with a deliberate divergence from the traditional anisotropic model. Figures 1 and 2 compare the conventional magnetic field with an SFM field arrangement. In the uniform magnetic field of a conventional magnet, a portion of the magnetic field is wasted. Whereas, in the SFM configuration, the magnetic field is shifted toward one side of the magnet, better utilizing the magnetic field.

SFM and Magnetic fields technology advantages:

- Higher field strength in the working zone for the mass and size of the magnet

- Substitution of higher-temperature, lower-remanence materials

- Increased design freedom, with less concern for handling stray field effects

- Reduction of overall system weight for equipment using the SFM

SHAPED FIELD MAGNET FABRICATION

Arnold’s patented process for SFM fabrication shapes the magnetic field as part of the magnet manufacturing process. The desired field shape is carefully plotted out beforehand so that the various stages of compression, sintering and magnetic field alignment work together to provide the desired field characteristic. Our quality processes and systems ensure your SFMs will perform optimally in your application.