Arnold Magnetic Technologies’ industry leading RECOMA Samarium Cobalt (SmCo) magnet materials break the performance barriers of other magnetic components. Offering several operational advantages, our top-of-the-line RECOMA 35E is currently the most power dense samarium cobalt magnet on the market, and is specifically created for the most demanding environments, including high speed (100,000 RPM+), high temperature (above 150°C) and highly corrosive environments, such as aerospace, motorsports, and automotive industries. As the market leader in high performance SmCo, Arnold Magnetic Technologies continues to push the boundaries of magnetic performance, while maintaining an integrated and sophisticated supply chain.

All locations in our RECOMA product’s supply chain are registered with ITAR and can adhere to DFAR clauses.

RECOMA GRADES 33E & 35E PROVIDE RECORD-BREAKING PERFORMANCE UNDER EXTREME CONDITIONS — FROM MOTORSPORTS TO AEROSPACE.

KEY BENEFITS OF SAMARIUM COBALT MAGNETS

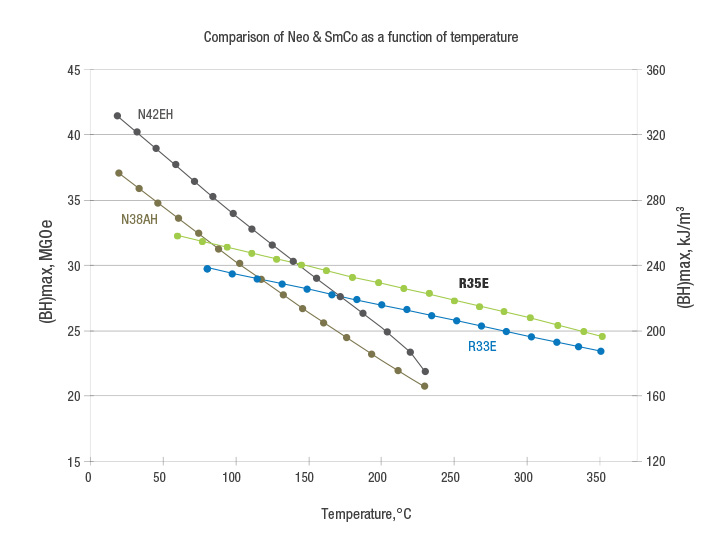

- Performance at temperature extremes – RECOMA samarium cobalt magnetic materials offer the world’s highest stability and magnetic output at elevated temperatures.

- Broad-based source of supply – Unlike neodymium (Nd) magnets, which need high levels of rare dysprosium (Dy) to function at moderate temperatures, SmCo magnets use materials that are more widely available and are inherently stable at temperatures well above the Curie point of NdFeB. This makes SmCo pricing more stable and less prone to market changes.

- Breadth of applications – Use Arnold’s RECOMA 35E to achieve higher performance and efficiency in your automotive, motorsports, aerospace, defense, or industrial application.

- Custom properties – Since we are an integrated supplier, we can adjust the composition of your material for performance at extreme temperatures up to 550°C, or for much lower temperature coefficients for sensitive applications.

Arnold’s custom SmCo magnets are made to your specification and project requirements.

RECOMA samarium cobalt grades 33E and 35E are ideally suited to the following applications:

- High Efficiency Rotors

- Drive Components

- Electric Motors

- Couplings

- Generators

- Sensor Systems

- Actuators

- Energy Recovery Systems

All locations in our RECOMA product’s supply chain are registered with ITAR and can adhere to DFARS clauses.

RECOMA® SAMARIUM COBALT MAGNETS GRADES AND PROPERTIES AT-A-GLANCE

Available in standard grades 18-35E, custom grades for high temperature and low reversible temperature coefficient, and in any shape needed for your application.

| RECOMA® Grade | BH max | BH max | Br | Br | Hcb | Hcb | Hcj | Hcj | Reversible Temp. Coef. of Induction | Max Oper Temp* |

|---|---|---|---|---|---|---|---|---|---|---|

|

|

kJ/m 3

|

MGOe

|

T

|

kG

|

k A/m

|

kOe

|

k A/m

|

kOe

|

%/K

|

°C

|

|

18

|

143

|

18

|

0.87

|

8.7

|

650

|

8.2

|

2400

|

30

|

-0.045

|

250

|

|

20

|

160

|

20.1

|

.90

|

9.0

|

700

|

8.8

|

2400

|

30

|

-0.045

|

250

|

|

22

|

175

|

22

|

.94

|

9.4

|

730

|

9.2

|

2400

|

30

|

-0.045

|

250

|

|

25

|

200

|

25.1

|

1

|

10

|

775

|

9.7

|

2400

|

30

|

-0.050

|

250

|

|

24HE

|

195

|

24.5

|

1.02

|

10.2

|

765

|

9.6

|

2000

|

25

|

-0.035

|

350

|

|

26

|

205

|

25.8

|

1.04

|

10.4

|

765

|

9.6

|

2000

|

25

|

-0.035

|

350

|

|

26HE

|

215

|

27

|

1.07

|

10.7

|

800

|

10.1

|

2000

|

25

|

-0.035

|

350

|

|

28

|

225

|

28.3

|

1.1

|

11

|

800

|

10.1

|

2000

|

25

|

-0.035

|

350

|

|

28HE

|

225

|

28.3

|

1.1

|

11

|

805

|

10.1

|

2000

|

25

|

-0.035

|

350

|

|

30

|

230

|

28.9

|

1.12

|

11.2

|

820

|

10.3

|

1600

|

20

|

-0.035

|

250

|

|

30HE

|

230

|

28.9

|

1.12

|

11.2

|

830

|

10.4

|

2000

|

25

|

-0.035

|

350

|

|

30 S

|

235

|

29.5

|

1.12

|

11.2

|

845

|

10.6

|

2150

|

27

|

-0.035

|

350

|

|

32

|

240

|

30.2

|

1.15

|

11.5

|

835

|

10.5

|

1350

|

17

|

-0.035

|

250

|

|

32 S

|

245

|

30.8

|

1.15

|

11.5

|

850

|

10.7

|

1790

|

22.5

|

-0.035

|

250

|

|

33E

|

251

|

31.5

|

1.16

|

11.6

|

865

|

10.9

|

2100

|

26.4

|

-0.035

|

350

|

|

35E

|

265

|

33.3

|

1.19

|

11.9

|

880

|

11.1

|

1800

|

23

|

-0.035

|

300

|

SAVE TIME – COLLABORATE EARLY

To learn more about our Samarium Cobalt high temperature magnets, and whether SmCo is the right material for your custom assembly, contact a specialist today.