High efficiency demands the best materials, and the Arnold L Type laminated rare earth magnets are proven to reduce eddy current losses in high efficiency motors. Fewer eddy current losses means lower heat and greater efficiency. esigners in the aerospace, automotive, motorsport, and industrial markets are turning to laminated rare earth magnets, and are working to balance the tradeoff between power and heat. Arnold minimizes the tradeoff by offering best-in-class materials with:

- The thinnest available insulating layers, <20 um

- Performance at temperatures up to 200˚C

- Magnet layers from .5 mm and up in custom shapes and sizes in neodymium iron boron or samarium cobalt

With a worldwide presence and extensive engineering expertise, Arnold can work with your design team to improve motor performance, delivering custom magnetic assemblies and even complete rotors. L Type magnets provide record-breaking performance under extreme conditions — from motorsports to aerospace. We collaborate on high efficiency motor designs using laminated rare earth magnets, precision thin metals, carbon fiber sleeving, and RECOMA samarium cobalt for total system performance. Made to your specification and project requirement, the L Type rare earth magnets are manufactured with Arnold’s proprietary processes for the thinnest layers and highest performance.

MODELING WITH L TYPE MAGNETS

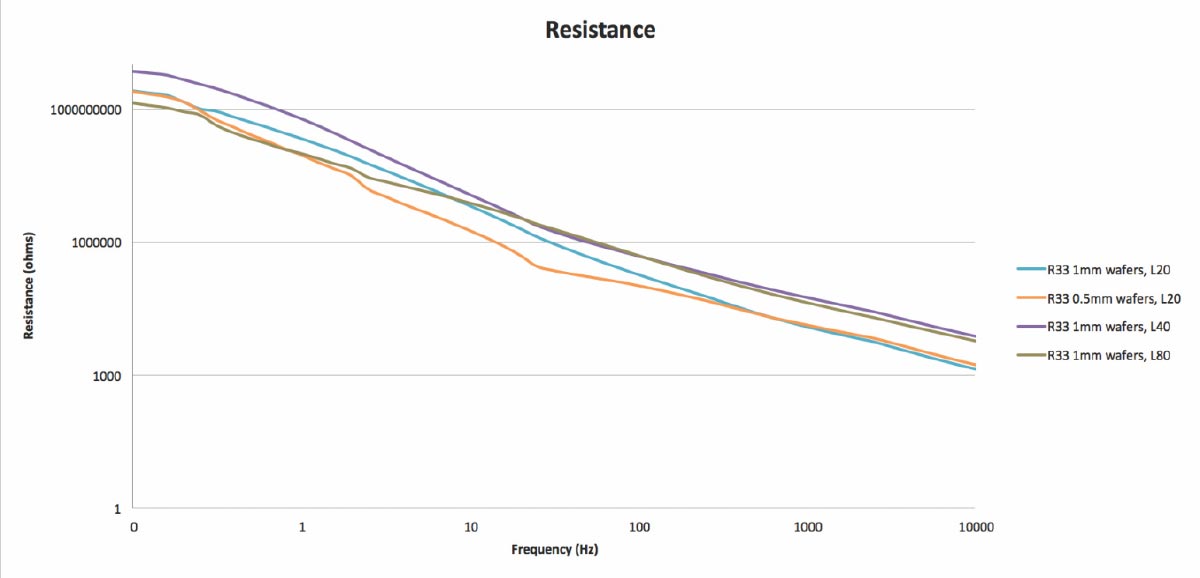

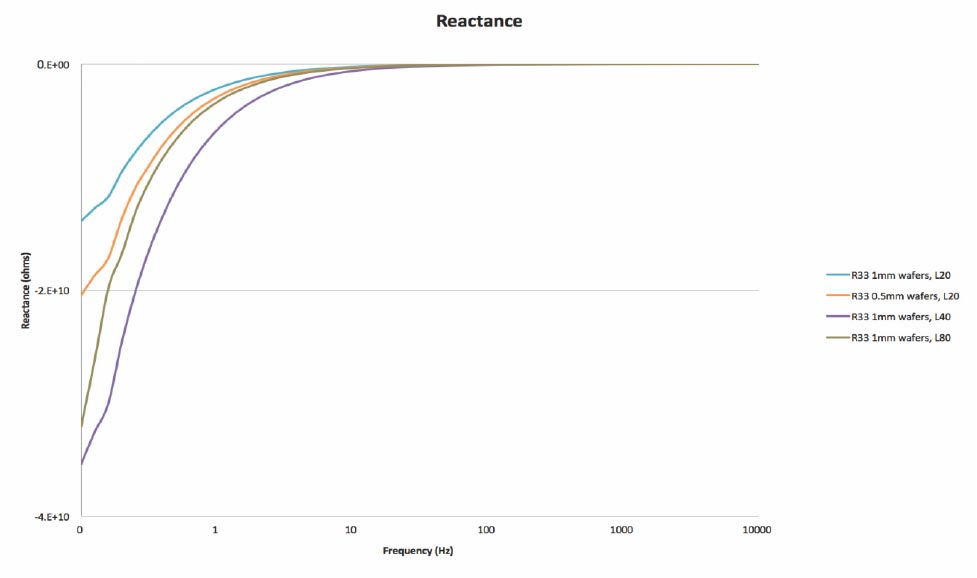

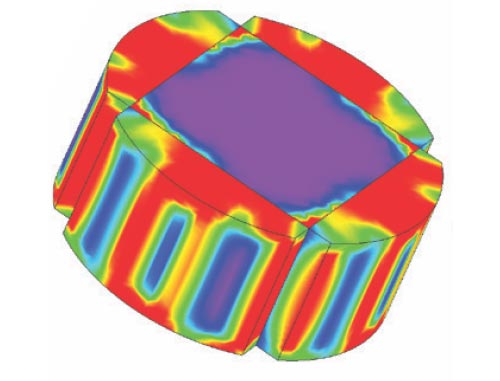

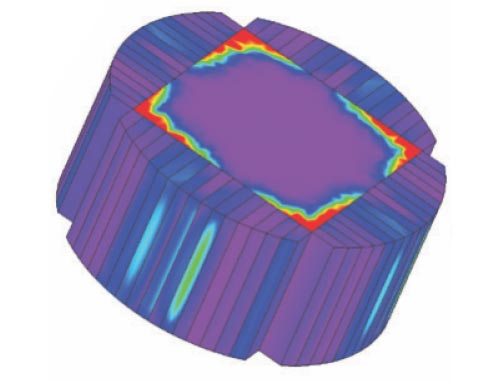

Calculation of eddy current losses with and without lamination are shown below. Our engineers can help to select an appropriate material and lamination thickness to perform optimally in your application, given your temperature and frequency requirements.

Without Lamination

With Lamination

ACHIEVE OPTIMUM PERFORMANCE

The optimal lamination for your application is a balance of the need for the greatest electrical resistance at the operating frequency and the best magnetic performance in the physical envelope of your application. Matching the right L Type insulation and magnet layer thickness to your application makes all the difference.

.5mm L20

96% magnet fill fraction

1mm L20

98% magnet fill fraction

1mm L40

96% magnet fill fraction

WHAT SIZE LAMINATE DO YOU NEED?

Validated by an independant, outside laboratory, 1mm L Type RECOMA 33E separated by 18 micron polymer lamination, the thinnest available, offers both optimal magnetic performance and lowest resistance for high ef ciency motor applications.