Arnold’s Engineering and Technical team have access to wide range of specialized instrumentation and tools to accurately test your system’s performance. Testing capabilities include a full suite of magnetic, physical and environmental tests.

MAGNETIC TEST CAPABILITIES

Magnetic Properties

Br, Hcb, Hci, Hk, Ms, BHmax, Recoil Permeability, and more. The primary tool used is a DC Hysteresisgraph. Values of Hci between 50 and 30,000 Oersteds can be successfully measured.

Magnetic Field Mapping

Linear, Planar and Rotary. Data and graphic output can be provided for objects up to approximately one cubic foot.

Magnetic Properties at high and low temperatures (-40 to 300 ºC)

Properties as above but tested at any temperature within the specified range.

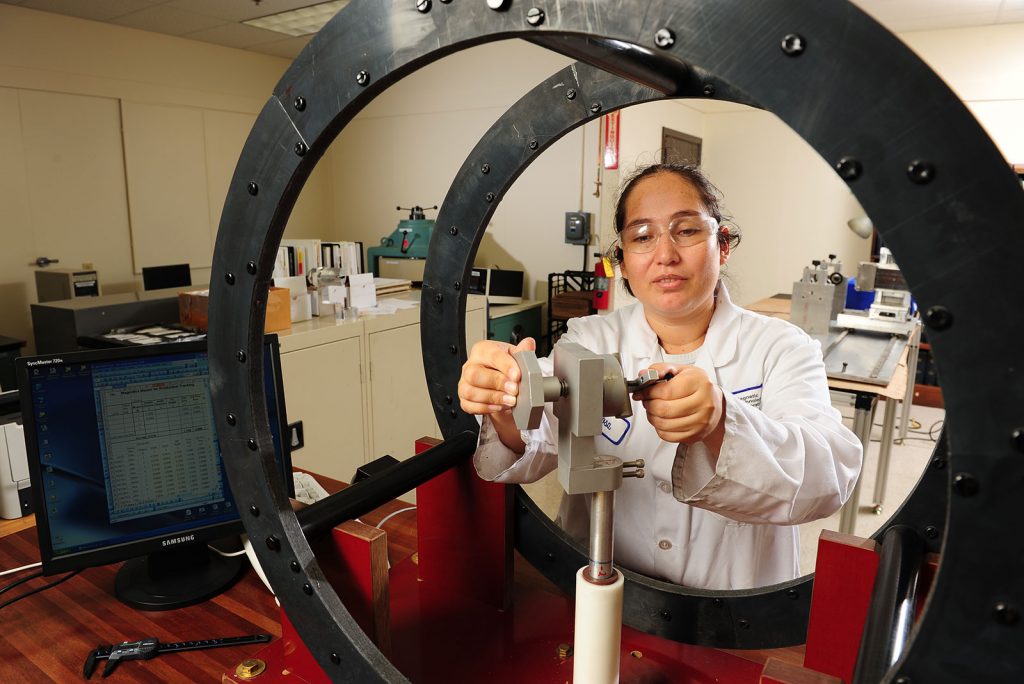

Fluxmeter measurements

Magnetic dipole moment, total field output and error angle measurements. Several measurement systems are available with coils up to 8′ in diameter, from 6″ to 96″; highly flexible manually operated systems and automated systems.

Reversible Temperature Coefficients

Measured and calculated for any range desired within the specified temperature limits.

Gauss measurements

Single measurements at specified locations or measurements using C-fixtures, yokes or customer-specified design.

AC magnetic measurements of toroids can also be performed. Contact us for sizes and measurement options.

PHYSICAL AND ENVIRONMENTAL TEST CAPABILITIES

Salt Spray

This is an attribute test performed to ASTM B-117. Results are usually expressed as “days-to-failure.” Photographs and micrographs can also be provided.

Autoclave, Uncoated Magnets

Often called the BCT test, it is a weight-loss test performed at 2 atmospheres (130ºC) and 100% RH. Duration is 96 hours, but can be adjusted per customer requirements.

Autoclave, Coated magnets

This is an attribute test looking for lack of failure at a specified test duration. Test conditions can be selected ranging from two atmospheres, 100% RH to HAST test conditions. A tape peel test can be performed at the end of the pressure testing.

Extreme temperature

This is accomplished by cycling the magnets or assemblies between extremes of temperature. Our labs can test between -40 and 343 ºC with manual exchange between chambers or between -40 and 175 ºC within the same chamber.

Physical Strength

Our Instron can be configured for tensile (pull), 3-point bend or for peel testing.