Every type of permanent magnet has a unique set of characteristics that can affect how is performs in various applications. When evaluating magnet options for your project, pay attention to the following:

1. Temperature

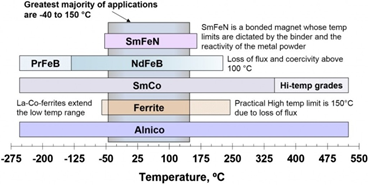

One of the most important parameters to consider when choosing a permanent magnet is the temperature of use. As one might imagine, the magnetic field is not constant; it changes with temperature, getting either stronger or weaker. The figure below shows the usable temperature range for each of the five commercially available materials. Conveniently, most applications utilize magnets between -40°C and 150°C, and all listed materials are usable within that range.

Because of their low cost, ferrite (hard ferrite, ceramic) magnets are still widely used. Note however, that ferrite magnets lose 25% of their flux output when heated from 20 to 150 °C. They also have relatively low energy products, typically 10% of rare earth magnets. So where device size and weight are important, such as hard disk drives and portable electronics (e.g. cell phones, hearing aids), rare earth magnets are necessary.

2. Availability

Issues of raw material price and availability are at the core of today’s discussion on permanent magnets. These factors are influenced by the general availability of the raw materials, geographic distribution, ease of recovery from mined ore, and open market trading. Of all the elements used in magnetic materials, rare earth elements have been the most problematic based on geographic limitations on sourcing. China still produces 90 percent of the rare earth oxides used each year and more than 95 percent of the rare earth metals and alloys. China also produces and consumes 80 percent of all permanent magnets. There is inconsequential production of neodymium-iron-boron (NdFeB) in the US. One alternative to neodymium magnets is samarium cobalt (SmCo), which has fewer sourcing limitations and performs better in higher temperature applications.

3. Magnetic Output

How strong a magnet is can be quantified by one of two key metrics. The first is residual induction, BR. If a permanent magnet is placed on a steel block, the force required to remove the magnet from the block is proportional to BR. BR is one of the magnet characteristics published by magnet producers.

The second key metric is maximum energy product, (BH)MAX. Maximum energy product is useful in calculating performance of motors. (BH)MAX is proportional to BR2. Each type of device benefits especially from either B (that is, BR) or B2 (that is,(BH)MAX or BR2) as described in this table of applications.

| General Description | Physical Laws | System Function Proportional to |

Application Examples |

| Conversion of mechanical energy | Faraday’s Law | B | Microphone Alternators, Generators Magneto Torque Transmitters |

| Magneto-static field to mechanical work |

Coulomb’s Law | B2 | Compass Reed Switches Torque Coupling (synchronous) Magnetic Separators Holding (attachment) Systems Magnetic Conveyors Magnetic Bearings |

| Interaction between current and magnetic flux | Lorentz Force Law | B | Motors: DC, BLDC, Synchronous, Stepping, Linear, Moving Coil Loudspeakers, Headphones HDD Voice coil motors Geophones Phonograph pickups Electrical measuring instruments |

| Magnetic Field Focusing Systems |

Lorentz forces on free charges | B | Dipoles, Quadrupoles Undulators, Wigglers Magnetrons, TWTs Mass Spectrometers NMR devices |

Read our in-depth article, Permanent Magnets in a Changing World Market.

Download our technical note for advice on choosing the right magnetic material here.